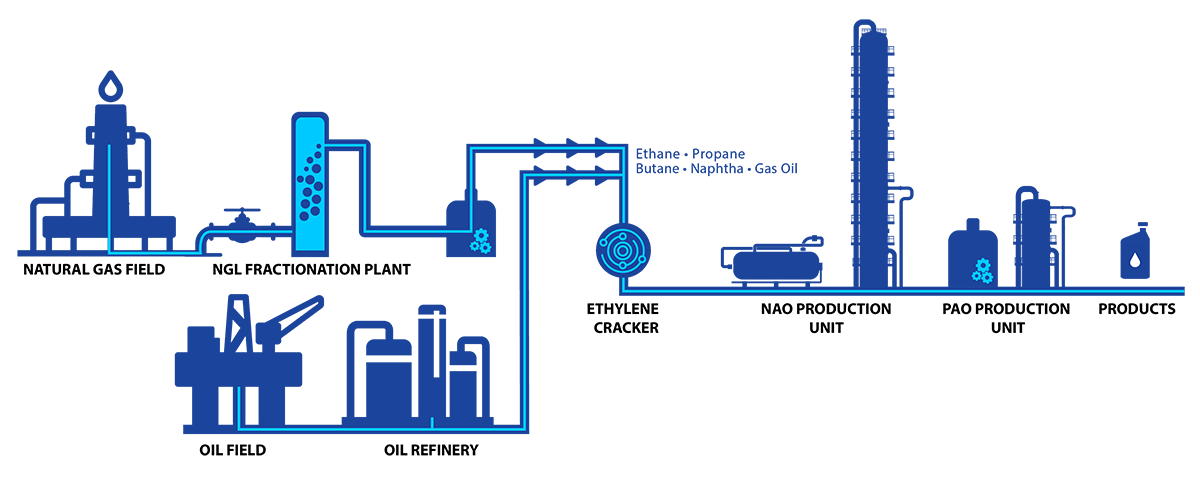

CPChem’s PAO history dates back to December 1980, when the continuous PAO unit in Baytown, Texas, started up. Since then, the company pioneered the production of 1-dodecene-based PAOs in 1995, which have grown steadily in popularity. CPChem has continuously expanded its production of PAOs through multiple expansions in Baytown, the 2011 acquisition of PAO assets in Beringen, Belgium, and mPAO production in Texas. Our most recent expansion in 2017 in Baytown expanded our production capacity to 58 KTA, and our 2025 expansion in Beringen doubles our European capacity to 120 KTA.

With more than 40 years’ experience manufacturing PAOs, CPChem continues to invest in the future, growing our production capacity to help meet the increasing demand for PAOs worldwide.